More sustainable applications of steam technologies in industry

More sustainable applications of steam technologies in industry, focused on energy efficiency and adapted to the limitation of atmospheric emissions. Steam is widely used as a means to supply energy to industrial processes, a challenge for boiler rooms, which are called to use increasingly sustainable steam technologies to adapt to environmental regulations that limit atmospheric emissions generated by the different fuels used in the production phases.

This requires the optimization of industrial plants in order to achieve efficient operation and, at the same time, operate safely and reliably.

Steam technology applications in industry

In general, industrial steam systems and boilers represent around 30% of the energy use of the manufacturing industry and there are not a few companies that use steam systems as fuel. This is for example the case of heating, cleaning, atomization, sterilization and other systems.

- Food processing

- Agricultural industry

- Chemical industry

- Paper industry

- Textile industry

- Building materials (concrete, glass, clay…)

- Service sector

- Heat in hotels, hospitals and laundries

The starting point for the optimization of a plant through steam technology applications in industry is the analysis of the situation of the equipment individually and the installation as a whole to implement energy efficiency plans and cost savings through control and the efficient use of steam, since the applications of updated steam technologies in the industry replace obsolete equipment and allow the automation of industrial steam systems.

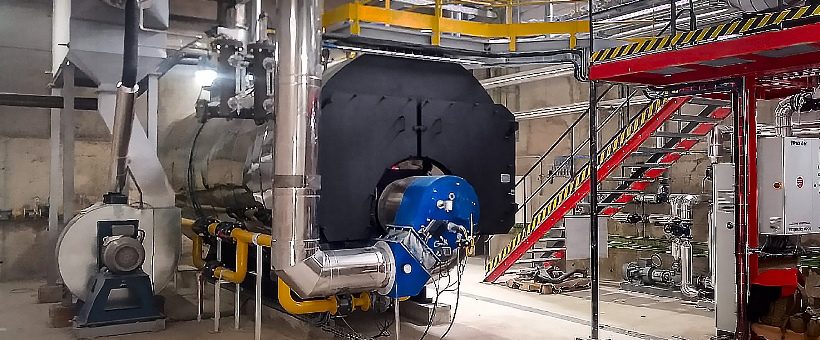

The process of improving and saving energy basically begins in the steam generation boilers and continues with the distribution of the steam, the heat recovery systems and the final use of steam. Although it is evident that the use of more efficient boilers and burners generates energy savings, the optimization of the entire steam system, taking into account valves, as well as instrumentation and control equipment, which allows generating greater energy savings .

Adapted and ecological steam technology

In recent years, innovation in combustion technologies has made it possible to develop burners with lower emissions even than the environmental requirements set forth by the new European regulations, says Iñigo Béjar, CEO of E&M Combustion, at the same time as investments to achieve energy savings through maintenance upgrades and low-cost upgrades to steam systems are easy, implementing updated technologies, replacing outdated equipment, and automating industrial steam systems, not to mention industrial steam replacements so thermal power plants don’t stop.

Committing to sustainability is a competitive opportunity for companies, which allows energy savings and improves the profitability ratios of the plant. Our Thermal and Combustion Engineering department and our technicians at the plant reveal the many opportunities for improvement in steam systems that promote greater energy efficiency in plants.

Thus, sustainability in steam technology applications in industry will focus on system efficiency and optimization of industrial steam systems.

Opportunities for improving energy efficiency in steam systems to minimize costs and increase efficiency potential have long been clearly identified. If until now this potential has not been exhaustively exploited, it is due to different organizational causes, corporate priorities on production instead of maintenance and even the lack of clear and incentivizing regulations and the uncertainty about the adoption of new technologies or new fuels. .

However, many of the optimization measures for steam systems also involve best operating and maintenance practices within continuous improvement in companies and guarantee that energy savings are sustainable over time.

- On 22/08/2022