Manufacture of boilers and pressure equipment for a petrochemical project

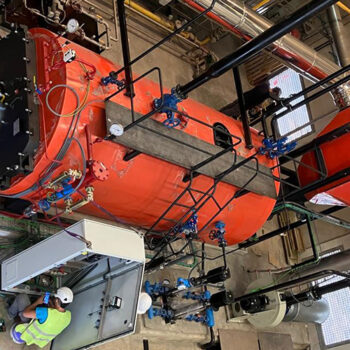

Soluciones Integrales de Combustión carries out the manufacture of boilers and pressure equipment for a petrochemical project in Eastern Europe.

As specialists in the design and manufacture of turnkey boiler rooms, the company is manufacturing two low-emission boilers, which will incorporate two ultra-low-emission burners in a Regulation and Measurement Station (ERM). of the aforementioned petrochemical plant. Emissions will be below 30 mg, much lower than usual in this type of facilities, with the aim of adapting to the new European environmental requirements.

The boiler room will be used for heating the gas, which arrives at a low temperature from the gas pipelines to the gas ERM, where it is heated, in order to adapt the gas supply specifications to the requirements of the plant. .

Very low emission boilers and burners

The low-emission boilers that are in production will operate with ultra-low-emission burners in a gas Regulation and Measurement Station (ERM) of a petrochemical company in Eastern Europe. The project will allow emissions to be below 30 mgs, much lower than usual.

One of the most relevant aspects of the project is respect for the demanding requirements regarding environmental protection, in line with those that form part of the community regulations in this field. In this way, the plant will be one of the most technologically advanced and will integrate petrochemical operations with the production of clean fuels, while optimizing the use of raw materials and resources from both processes. This will make petrochemical activities compatible with the objectives of the energy transition.

Manufacture of boilers and pressure equipment

Industrial boilers are heat or steam generators for use in industrial production processes. Integral Combustion Solutions carries out the design and manufacture of boilers and pressure equipment for process and electrical energy production plants. Boilers are responsible for transforming fuel energy into heat to heat a process or into water steam, depending on the desired temperature and pressure, to be transported to its point of consumption through pipes.

On the other hand, in the case of steam boilers, the water requires chemical and thermal treatment before entering the boiler, so that its evaporation does not generate impurities or sediments in the boiler.

A boiler is understood as any pressure device where the heat from any energy source is transformed into usable means of transport, either liquid or steam.

The concept of pressure equipment includes both installations with pressure equipment and the equipment itself, understood as tanks, pipes, safety accessories and pressure accessories with a maximum pressure of 9.5 bars.

Industrial applications

The applications of Soluciones Integrales de Combustion industrial boilers are adapted to each production process according to its thermal needs, which is why they are very varied. They are critical equipment in cogeneration or district heating processes or in the food industry such as canning, bottling, processing, oil, liquor and alcohol processing, wineries, beer and dairy.

Soluciones Integrales de Combustion´s boilers are also present in the rubber, ceramic, chemical, metal, cement and prefabricated concrete industries, paper and cardboard industries, pharmaceuticals, paint, glass and waste recovery.

The company builds High Power boiler rooms, and is responsible for the sizing and installation of gas, water, steam, etc. pipes; as well as the electrical installation and interconnection of all the elements of the room; automation and control and the supply and installation of water treatment appropriate to the facility to extend the life of the equipment and optimize energy savings, ending with the legalization of the thermal power plant.

The turnkey offer of Soluciones Integrales de Combustion consists of the planning and execution of energy installations. Its main areas of activity include the supply of industrial boilers, burners, high-power boiler rooms, instrumentation and control, and technological leasing.

- On 22/10/2023